Home ideas - 09 December 2019

Specifications for stone sills, thresholds, and stairs

Good specifications, capable of correctly describing a work, help to obtain a correct price for the work right from the design phase.

An overly generic description does not put the person quoting in a position to give a true price for the work or item requested, resulting in it being priced too high or too low.

The purpose of this short guide is to help the designer understand which elements generate costs when quantifying the final price of stone stairs, sills, and thresholds, making it possible to provide the right quantities during calculations in order to present real prices.

Viewing the problem from the stonemason’s point of view, requests are often absolutely incomplete and cannot be quoted correctly. Ironically enough, the first element that is missing is a clear-cut identification of the material! Pietra serena (grey sandstone), Carrara marble, Rapolano stone, or granite, will all have different costs! And even within these types of materials there are many subcategories. Speaking of travertine, light or dark? Cross-cut or vein cut?

So, first of all, we need to describe the required material as accurately as possible in terms of type and colour.

- After that, the thickness is obviously essential. Thicker material is more costly, as is its transport to the construction site.

Natural stone is more or less resistant to wear, so the choice to increase the thickness can be justified only for appearance purposes, for example in sills or stairs, where the thickness is visible. Generally, the greater the thickness, the more prestigious the work appears.

For example, in a staircase, there is no need to have thicker risers, where a thickness of 2 cm is absolutely sufficient. The standard for the treads, on the other hand, is 3 cm. - Another parameter to be indicated clearly is the material finish: polished or glossy? Brushed? In Rapolano stone or travertine? Filled?

Each of these processes has its own complexity, which has a cost. Not stating how we want the surface of the stone to be finished leaves out information, which makes it difficult to determine a correct price. - And then there is the machining of the slab ribs. If they are simply sawed, there is no need to indicate anything, but if the rib is visible, should they be polished and bevelled straight? Or have a bullnose edge? Or have a notch or rabbet? All these processes have a cost per linear metre. So, you have to indicate the edge finishing quantities.

- The drip edge on the sills must also be indicated in linear metres. And also, if they will be installed flush with the wall or overhanging. An overhang requires machining the 3/5 cm that the sill (or threshold) will overhang.

Not having this information will often lead to paying for work where it is not necessary.

The following are correct specifications that each designer should complete with his own indications.

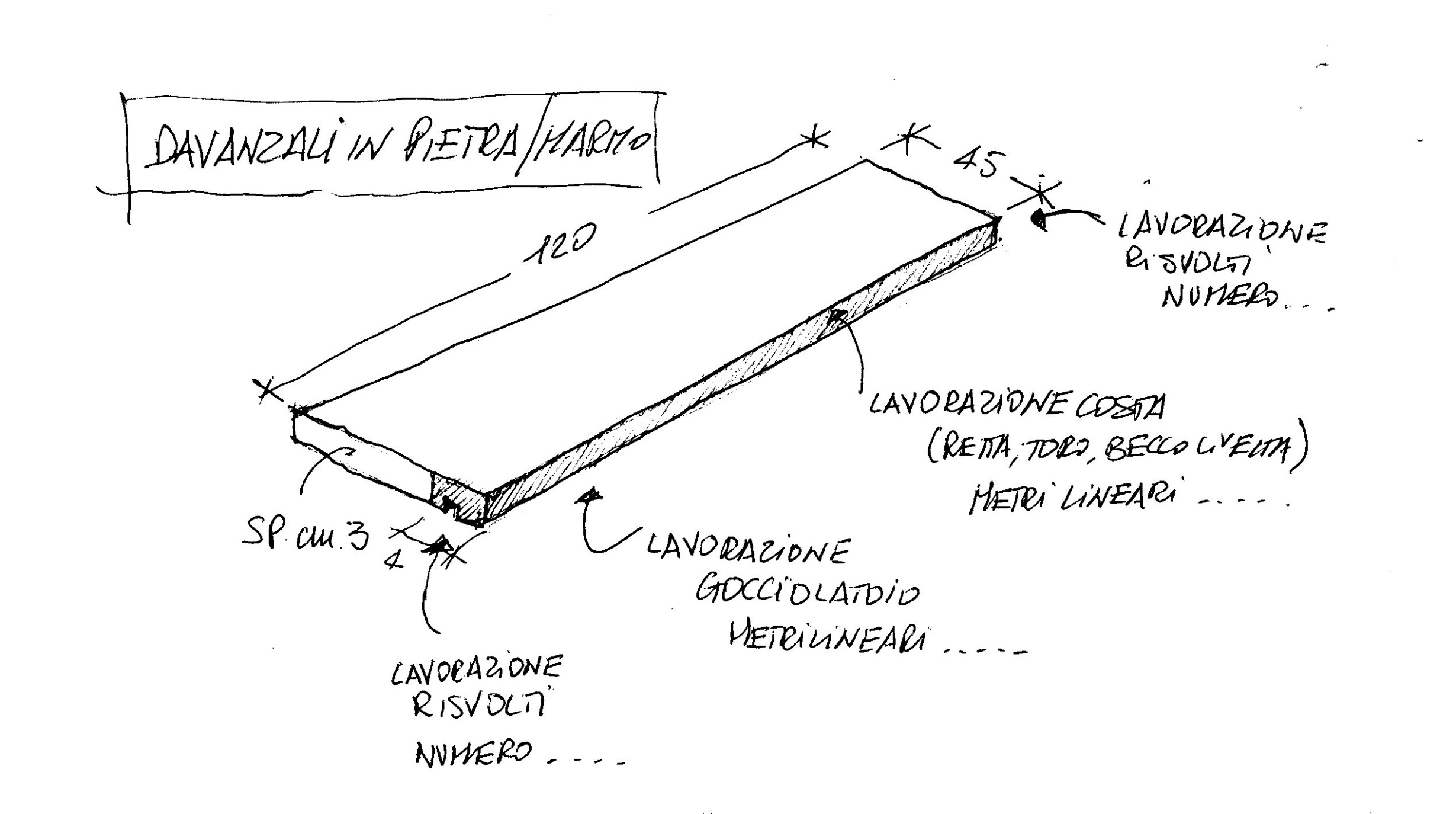

SPECIFICATIONS FOR STONE SILL

Sill in ________ (provide as many specifications as possible regarding the stone material chosen in terms of type of stone, colour, and surface finish) ___ cm thick (the sufficient standard is 3 cm). (It would be important to indicate maximum or minimum sill sizes and the total number. Different stones have different block sizes. Knowing the measurements of the work to be done helps to get a correct quotation. PS: this item is expressed in square metres).

The following is an example of correct specifications.

Rapolano stone sills, Colour PDR 013, stuccoed and polished finish, 3 cm thick. The size of the pieces will be 45 cm with lengths varying from 70 to 200 cm. The total number of sills will be 70). The sills protrude 3 cm from the outer wall face and are equipped with a drip edge. Inside, the thickness of the sill will be covered by the window frame (and therefore will not need any finishing). The visible ribs will have a straight and bevelled finish.

- 3 cm thick material – Tot. 42.00 m2

- Straight edge machining – 93 LM

- Drip Edge machining – 93 LM

- Side machining for 4 cm per side – 140

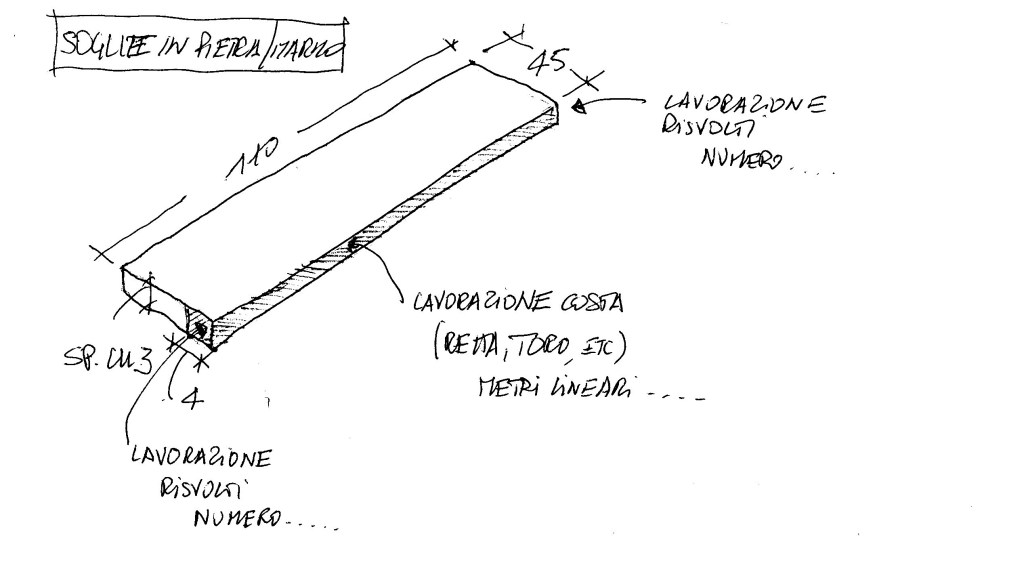

SPECIFICATIONS FOR STONE THRESHOLD

Threshold in ________ (provide as many specifications as possible regarding the stone material chosen in terms of type of stone, colour, and surface finish) ___ cm thick (the sufficient standard is 3 cm). (It would be important to indicate maximum or minimum threshold sizes and the total number. Different stones have different block sizes. Knowing the measurements of the work to be done helps to get a correct quotation. PS: this item is expressed in square metres).

The following is an example of correct specifications.

Rapolano stone thresholds, Colour PDR 013, stuccoed and polished finish, 3 cm thick. The size of the pieces will be 45 cm with lengths varying from 70 to 200 cm. The total number of thresholds will be 70). The thresholds protrude 3 cm from the outer wall face and are not equipped with a drip edge. Inside, the thickness of the threshold will be flush with the floor (and therefore will not need any finishing). The visible ribs will have a straight and bevelled finish.

- 3 cm thick material – Tot. 42.00 m2

- Straight edge machining – LM 93

- Side machining for 4 cm per side – 140

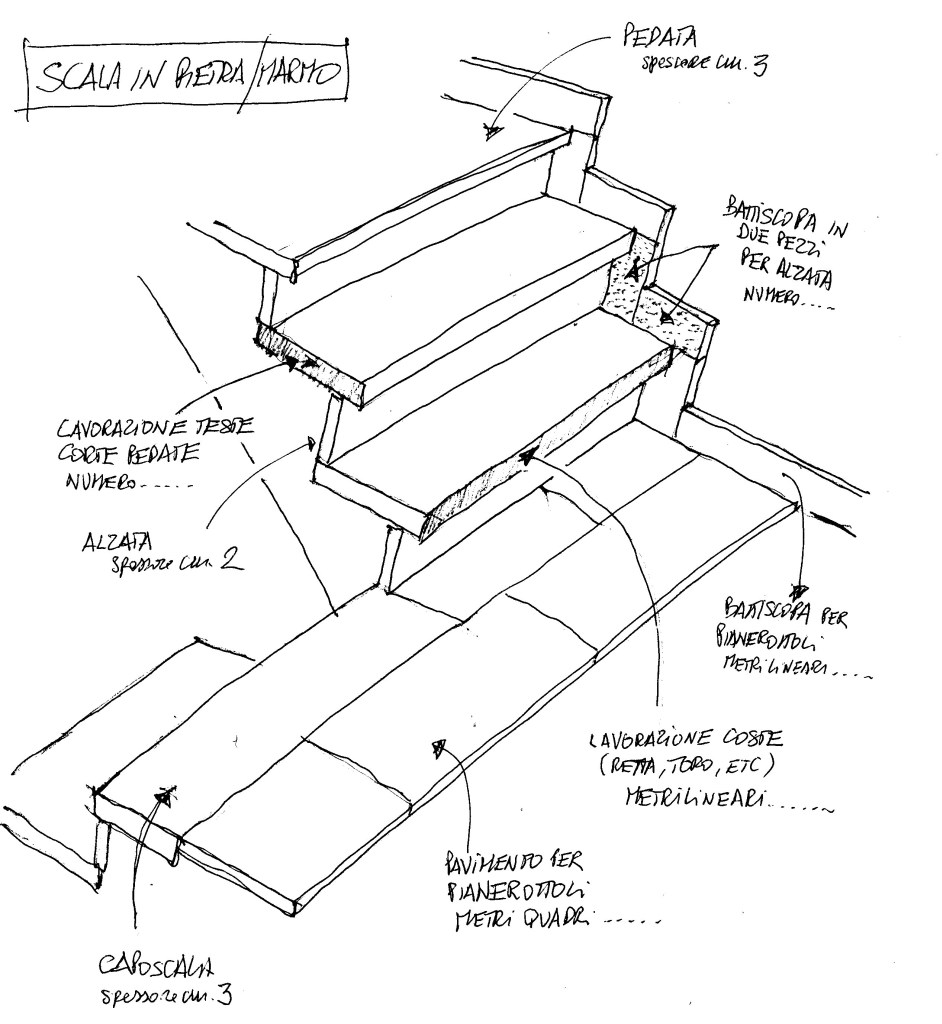

SPECIFICATIONS FOR STONE STAIRCASE

Staircase in ________ (provide as many specifications as possible regarding the stone material chosen in terms of type of stone, colour, and surface finish) ___ cm thick (the sufficient standard is 3 cm for the tread and 2 cm for the riser). It is particularly important to indicate whether the staircase is between two walls or has an exposed side. This determines the need for machining on the short side and the number of pieces of skirting required for the staircase (if requested). It is also important to quantify the square metres of any stairs that will not be made from trapezoidal rather than rectangular steps, because the cost of the pieces for making them is higher than for straight cut pieces (it would be important to indicate the measurements of the treads and risers and the total number. Different stones have different block sizes. Knowing the measurements of the work to be done helps to get a correct quotation. PS: this item is expressed in square metres).

The following is an example of correct specifications.

Rapolano stone staircase, Colour PDR 013, stuccoed and polished finish, 3 cm thick. The treads will be 35 cm x 120, with a thickness of 3 cm. The risers will be 120 x 14 with a thickness of 2 cm. There will be 120 treads and 120 risers to be made, 60 internal and 60 open on one side. The visible ribs will have a straight and bevelled finish. The staircase requires skirting.

- 3 cm thick material – Tot. 50.40 m2

- 2 cm thick material – Tot. 20.16 m2

- Straight edge machining – LM 72

- Machining on short side of treads – 140

- Skirting in two pieces for each riser. 180

- Skirting for landings, height 8 cm – ML 20

- Floor for landings 40x40x1.3 – 15 m2

(Please Note, the quantity calculations are not exact)

Rapolano stone staircase, TRAPEZOIDAL STEPS, Colour PDR 013, stuccoed and polished finish, 3 cm thick. There will be 12 trapezoidal steps on a staircase 120 cm wide, with a thickness of 3 cm. The risers will be 150 x 14 with a thickness of 2 cm. The visible ribs will have a straight and bevelled finish. The staircase requires skirting.

- 3 cm thick material – Tot. 8.64 m2

- 2 cm thick material – Tot. 2.50 m2

- Straight edge machining – LM 18

(Please Note, the quantity calculations are not exact)

By adhering to these items, the person providing the quote for the requested items will be able to provide a much more accurate and definitive quote, which will only vary depending on the quantification of the final working measurements, which can be found on the construction site.

We remain at your disposal for any suggestions and advice you may need during the design phase.